From Disposal to Recycling: The Lifecycle of EV Battery Packs (PDF)

One common concern regarding electric vehicles (EVs) revolves around what happens to their battery packs once they reach the end of their operational lifespan. While the initial thought might be to dispose of them in landfills, several companies are actively addressing the issue of EV and lithium-ion battery recycling. Among the notable players in this field is Li-Cycle, a company founded in 2016.

Like all lithium-ion batteries, those found in early Nissan Leafs or old iPhones eventually near the end of their service life. As time passes, these batteries may degrade significantly or develop faults necessitating replacement.

What Becomes of These Old Unusable Batteries?

This raises a pertinent question. With the implementation of innovative recycling techniques, there are now means to salvage these batteries and repurpose their components for future battery applications.

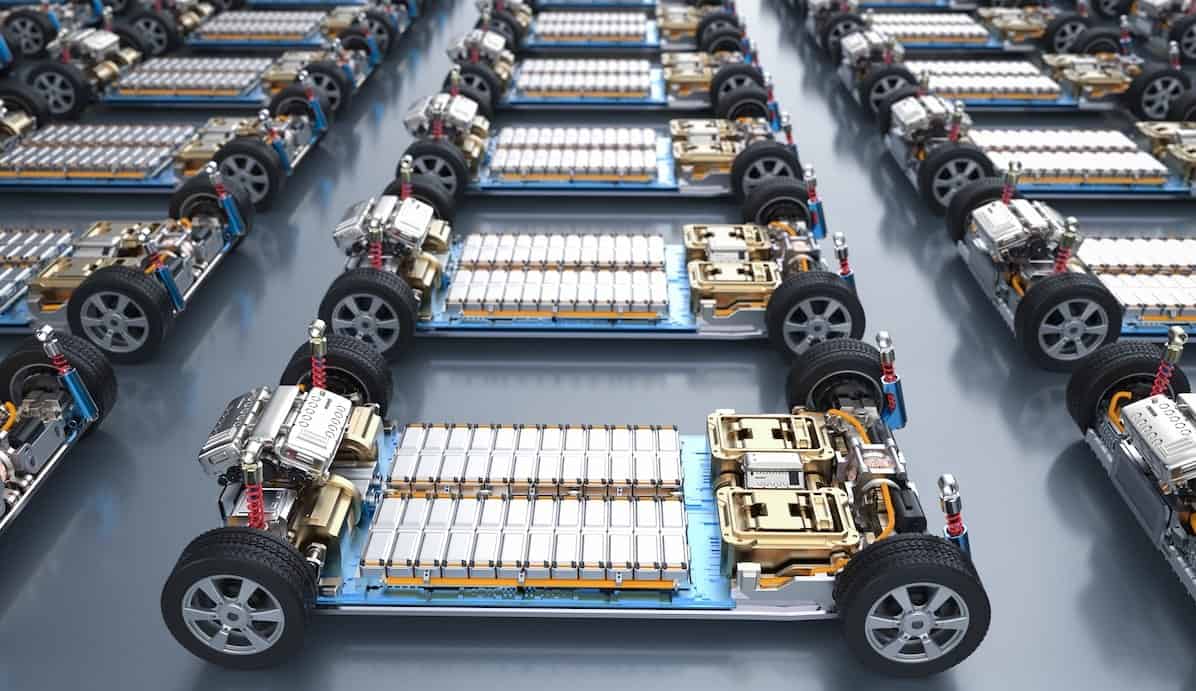

Inside these batteries lie valuable materials such as lithium, cobalt, copper, and nickel. These materials, in their pure elemental forms, are recyclable an infinite number of times. Li-Cycle is capitalizing on this chemistry.

The company operates a manufacturing facility in Arizona dedicated to recycling various types of lithium-ion batteries. Whether it’s a Tesla Model S battery pack or a battery pack from an electric leaf blower, Li-Cycle can recycle them all, thanks to its proprietary “water-based solution.”

In essence, the company doesn’t melt down the batteries; instead, it employs the solution to separate the battery pack components into three distinct containers. At the end of the process, these containers contain plastic scraps, aluminum and copper, and a bag referred to as “black mass.”

The black mass bag contains valuable materials such as lithium, nickel, and cobalt. After collecting these materials, they are shipped to different locations for further separation.

Manufacturers can then use these recycled elements to produce new lithium-ion battery packs. Essentially, Li-Cycle’s efforts “close the loop” in the lifecycle of a lithium-ion battery.

Li-Cycle claims that its Arizona facility can process up to 18,000 tons of lithium-ion batteries annually and can recycle up to 95% of the batteries’ resources.

What Is the Fate of The Battery Packs?

One of the persistent concerns surrounding electric vehicles is the fate of their battery packs once they reach the end of their useful life. Are they simply discarded and left to languish in landfills?

To answer this question, we can look at the precedent set by the disposal of smaller high-voltage battery packs, such as those used in the Toyota Prius and the Honda Insight. These packs do not end up in landfills at the end of their life.

Instead of discarding these batteries, auto recyclers, formerly known as junkyards, send them to specialized firms that dismantle the packs and break them down into their constituent materials, including wires, circuitry, plastics, and the actual cells. The cells and circuits are crushed to separate and purify various metals within them, including nickel and lithium.

Dealerships also responsibly dispose of used hybrid packs, relying on collection programs established by automakers, which send these batteries to the same recyclers for dismantling. Toyota’s program is particularly noteworthy, given the company’s significant presence in the hybrid vehicle market in the U.S.

When it comes to electric-car battery recycling, despite the significantly larger energy capacity of EV batteries compared to hybrid ones, the recycling process is quite similar. The battery packs are shipped to specialized facilities for disassembly and recycling. Common materials like steel, copper, and aluminum are typically recycled into the nationwide metals-recycling stream. While plastics may not be recyclable, they constitute a small proportion of the total contents of an EV battery pack.

A Great Opportunity for Business

The most desired part of these batteries is the cells themselves, which are the most expensive component of the entire battery pack when new. These cells contain valuable materials like lithium, cobalt, manganese, nickel, and, to a lesser extent, aluminum. The cells are ground up, and purified through various methods, resulting in a pure supply of these valuable metals.

Recycling is a lucrative industry in various sectors, including the automotive industry, with metals like steel and aluminum, which make up a significant portion of a car’s structure, often being recycled at the end of a vehicle’s life. However, EVs stand out due to the unique battery metals they contain.

In 2017, JB Straubel, a Silicon Valley tech entrepreneur with extensive experience in auto startups and an early employee of Tesla, launched Redwood Materials, a company aimed at scaling up battery collection and recycling. Redwood Materials is now based in Carson City, Nevada, near Tesla’s battery-manufacturing facility in the Reno area. Straubel’s focus on supplying battery minerals spurred an investment race, with numerous venture-funded startups and corporate entities emerging in the battery-recycling industry.

Redwood Materials’ primary challenge lies in securing an adequate supply of EV batteries for recycling. The company has established partnerships with auto-recycler trade groups and automakers, including Ford and Volkswagen, to increase its supply of used cells for processing. The U.S. Department of Energy has also supported Redwood with a $2 billion loan to expand its Nevada factory.

Can EV Batteries Be Re-used?

An EV battery pack is considered at the end of its life when it retains no more than 70 to 75 percent of its original capacity, which can take a decade or more to reach. Even with a quarter or more of peak capacity lost, aging battery packs still offer substantial energy storage, ranging from 20 to 90 kilowatt-hours, equivalent to up to three typical American home’s electricity usage for a day. It has long been envisioned that a robust “second-use” industry could emerge to purchase and repurpose used packs, extending their lifespans by another decade or more.

However, such an industry has not materialized at scale. While automakers have implemented early demonstration projects, and some energy-storage installations utilizing used EV packs are operational in various countries, potential customers for on-site energy storage still tend to favor new cells over a mix of used EV packs with uncertain usage histories and duty cycles (essentially, wear and tear from previous use).

The challenge of reuse is particularly challenging because new cells have become significantly cheaper, to the point where it’s unclear if there’s a viable business model in buying, transporting, repurposing, and reselling used cells from older battery packs.

The Future of EV Battery Recycling

What is likely to prevent used battery packs from being discarded into landfills is the presence of valuable metals within them: lithium, nickel, cobalt, manganese, and aluminum. Demand for batteries is set to surge in the 2020s and ’30s as major car markets such as China, North America, and Europe transition to electric vehicles. Establishing new mining operations takes considerable time, especially in regions with stringent environmental regulations.

Unlike liquid hydrocarbons, which lose their energy content after being burned as gasoline, a cobalt atom remains a cobalt atom, regardless of how many batteries it has been part of. Thus, end-of-life EV batteries offer a future source of these valuable metals, already extracted from the earth and readily available.

While the process of separating and processing battery packs and their cells and modules is necessary, recycled battery metals have a significant advantage over newly mined cobalt or nickel: they are already located in North America. The Inflation Reduction Act signed by President Biden includes substantial subsidies for U.S. battery production through the 2030s.

The EV purchase incentives outlined in the Inflation Reduction Act apply exclusively to vehicles with battery minerals sourced from specific countries, excluding China, which currently supplies most of the world’s EV battery metals. However, once a U.S. recycler separates the cells into their constituent metals, that “new” lithium or nickel is considered to originate from the U.S.

In Conclusion

You need not worry about the disposal of your EV’s battery pack at the end of its life. Chances are it will be meticulously collected and disassembled into its component parts, with its fundamental materials being reused in the production of new batteries, perhaps even for your next EV.

If you are looking to buy an electric vehicle or a new car car, and need a car appraisal, contact us and get a FREE quote